Slitting machines play a pivotal role in various manufacturing processes, especially in industries dealing with flexible materials such as films, foils, and paper. The purpose of these machines is to cut large rolls of material into narrower strips, making them easier to handle and process. This article explores the different types of slitting machines, the materials they handle, their design features, and highlights some notable examples available on the market, particularly from TW Machine, a leading manufacturer in the field.

Types of Materials in Slitting

Slitting machines are designed to process a wide range of materials, including:

- Flexible Films: Commonly used in packaging, these materials can be made from various plastics such as polyethylene, polypropylene, and polyester.

- Foils: Aluminum foils are frequently slit for applications in food packaging and insulation materials.

- Paper Products: From printing paper to specialty papers, slitting is essential in the paper manufacturing process.

- Textiles: Fabric slitting machines cater to the textile industry, allowing precise cutting of various cloth materials.

Plastic in Slitting Processes

Plastic materials, given their versatility and widespread use, demand specific considerations in slitting operations. Different types of plastics require tailored slitting settings—temperature adjustments, blade types, and tension controls—to ensure quality cuts without damaging the material.

Machine Design Considerations

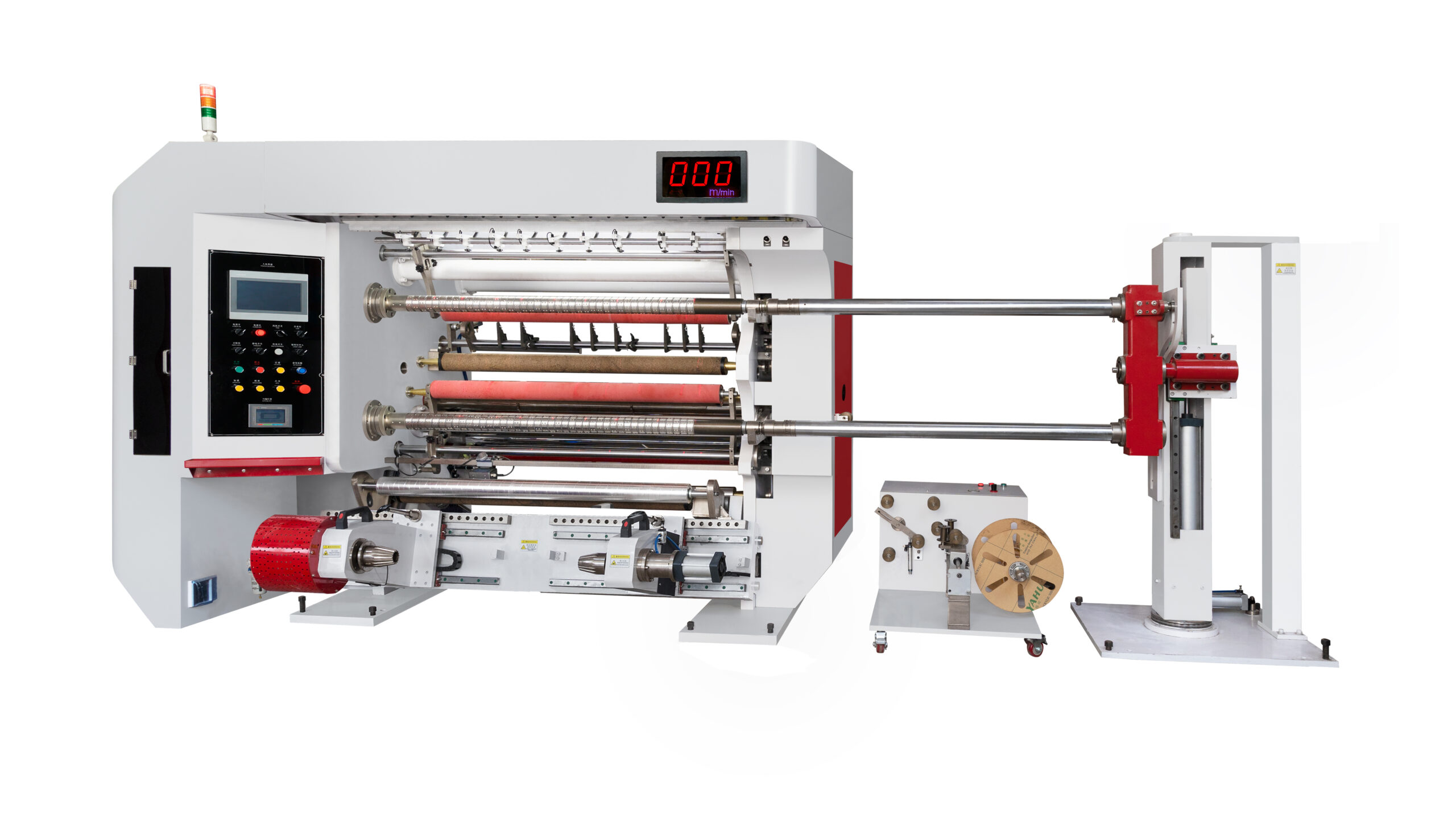

The design of slitting machines is crucial for efficiency and precision. Key aspects include:

- Blade Configuration: Machines may use razor blades, circular blades, or rotary blades, depending on the material and width of the strips required.

- Tension Control: Advanced slitting machines provide automatic tension control to maintain the integrity of the material being processed.

- Speed and Performance: High-speed machines can significantly enhance productivity, while user-friendly interfaces simplify operation and monitoring.

Notable Machines from TW Machine

TWM Machine is renowned for its innovative designs and high-performance slitting machinery. Their offerings include a range of models tailored to various industrial needs, emphasizing efficiency and precision:

- High-Speed Slitting Machines: Designed for maximum output, ideal for firms needing to process large volumes.

- Compact Slitting Lines: Perfect for smaller operations or facilities with limited space, providing the same level of performance in a reduced footprint.

For detailed specifications and a comprehensive catalog of their products, you can visit TWM Machine’s catalog page, where you will find an extensive selection of slitting machines, along with information on their features and applications.

Conclusion

In conclusion, slitting machines are essential for a wide array of industries that require the efficient cutting of materials into narrower strips. Understanding the materials being processed, the importance of machine design, and exploring leading manufacturers like TWM Machine can significantly enhance production capabilities. For further insights and product selections, don’t forget to check out the catalog page on TWM Machine’s website.

No responses yet